TOP-PELLET ®Extrusion Grades

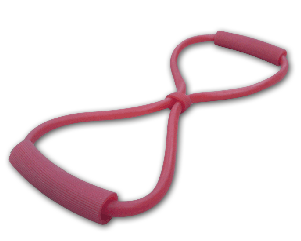

TOP-PELLET ® extrusion grade materials have certain characteristics, such as: Low hygroscopicity, high thermal stability at extrusion temperature, viscosity temperature characteristics not undergoing rapid change, balanced viscosity and slipping properties that will not cause slips, and retains good shape after extrusion molding, thereby being suitable for extrusion processing. The materials can be developed according to the clients’ customization requirements. They are widely used in the production of yoga stretch bands, exercise elastic ropes, medical tourniquets, vehicle trim strips, imitation wood railings, bicycle brake cable sleeves, and transmission wires, etc.

Based on SBS/SEBS thermoplastic elastomers, TOP-PELLET ® extrusion grade materials offer excellent processing performance that can effectively solve the high processing costs and pollution issues for vulcanized rubber; while also address the poor resistance to cold weather of PVC and the toxic materials that are generated during its processing.

TOP-PELLET ® extrusion grade materials do not generate toxic materials during the extrusion process and can be repeatedly recycled for reprocessing ,and offer processing advantages in environmental protection and cost reduction of raw materials. Furthermore, they comply with the international environmental protection regulations, including ROHS, REACH and California Proposition 65.

Properties and daily applications of TOP-PELLET ® Extrusion grade materials:

Features:

Can be either hard or soft. Comprehensive hardness range Shore A: 25A ~ Shore D: 75D

Good elasticity

Excellent tenacity and durability

Good dimensional stability

Application in household supplies:

Yoga stretch band, exercise elastic rope, chest exercise stretch band, medical tourniquet, vehicle trim strip, imitation wood railing, bicycle brake cable sleeves, transmission wire, door and window trim strip, IC tube materials.

EX Series

EX SERIES: SEBS BASE MATERIAL. USE FOR WINDOW GASKET,EXERCISE BAND, IC TUBE APPLICATION.

Applications